Eaves and Vents Experiments (EaVE) Phase A

Research Overview

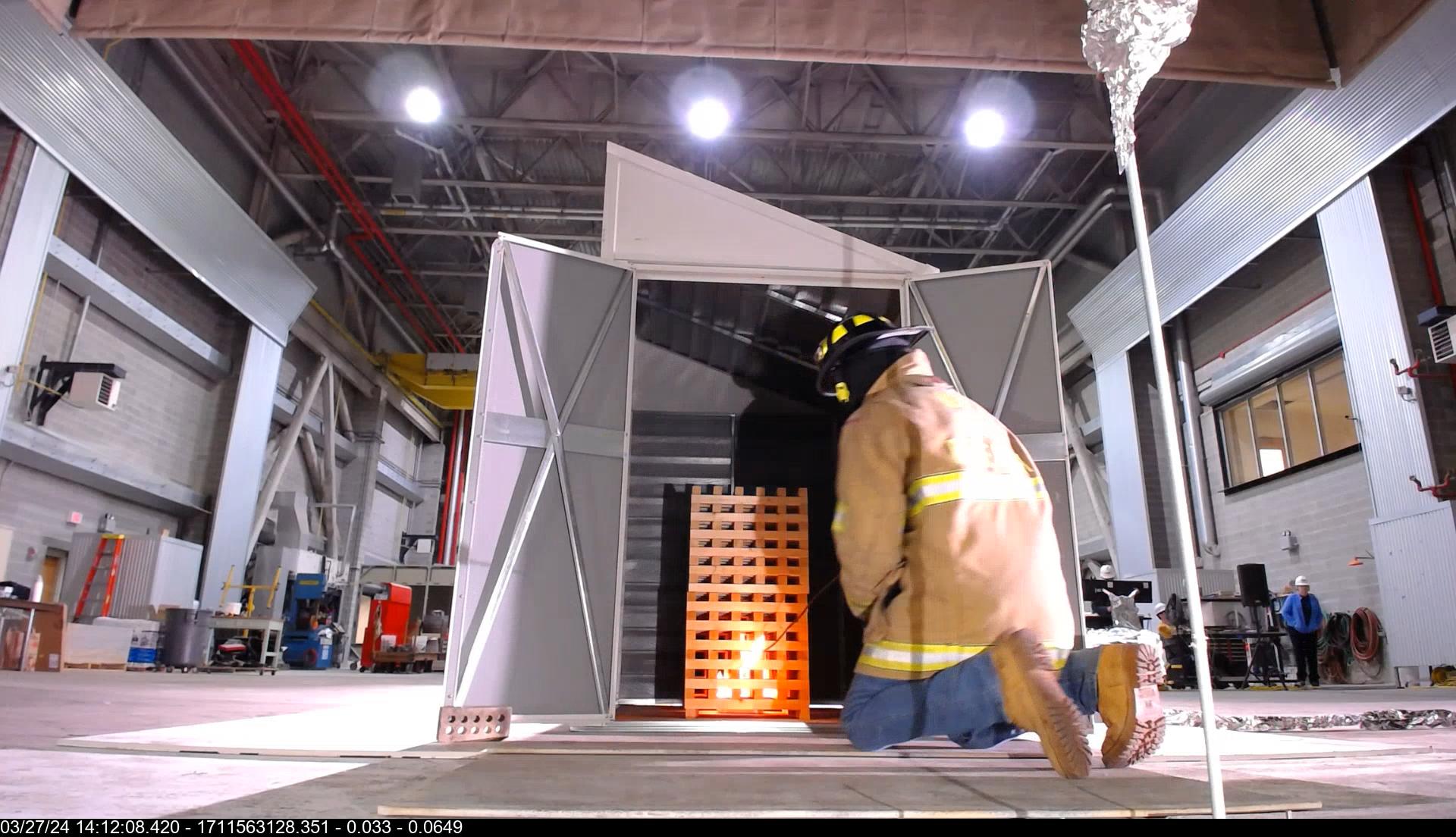

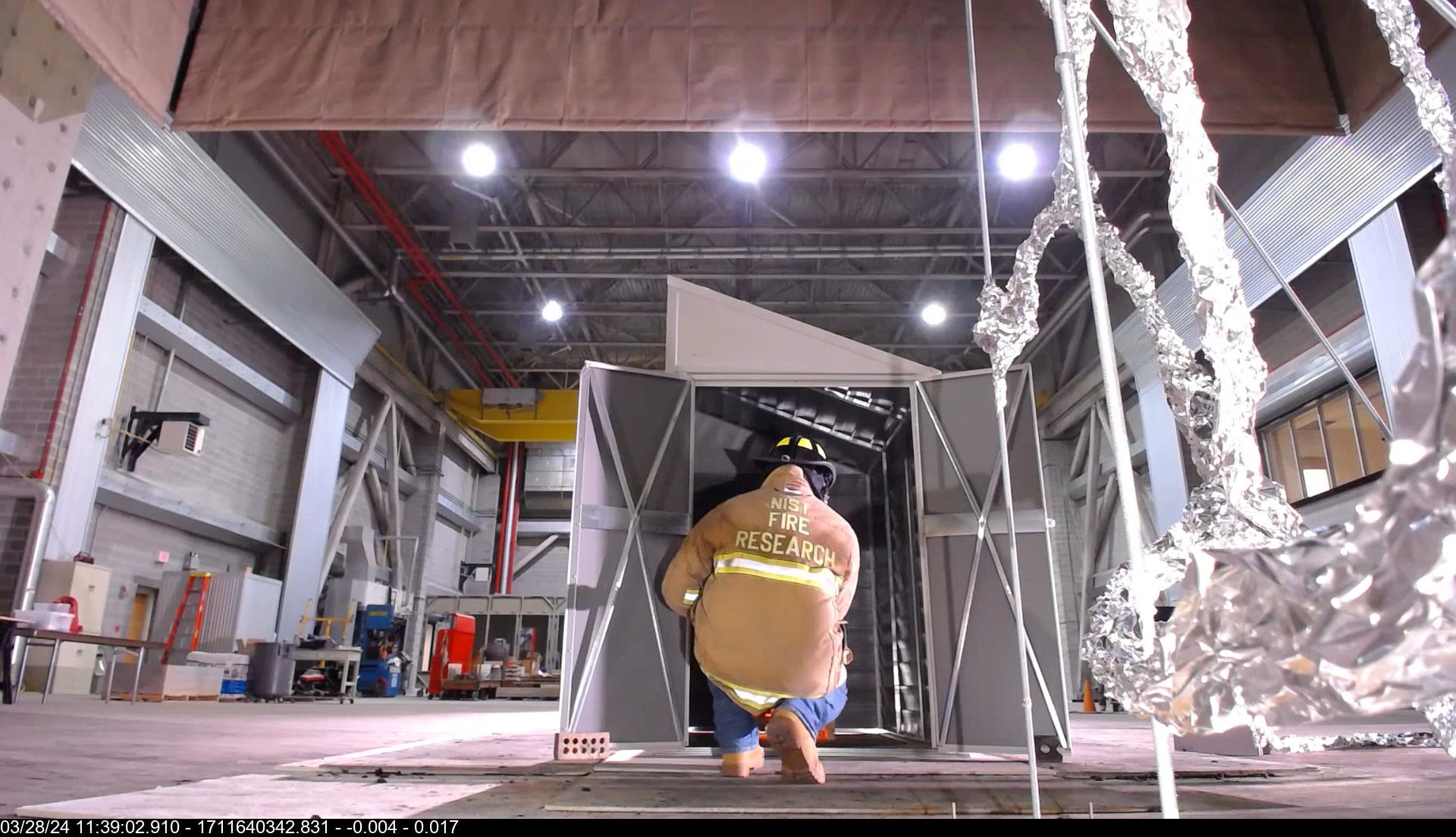

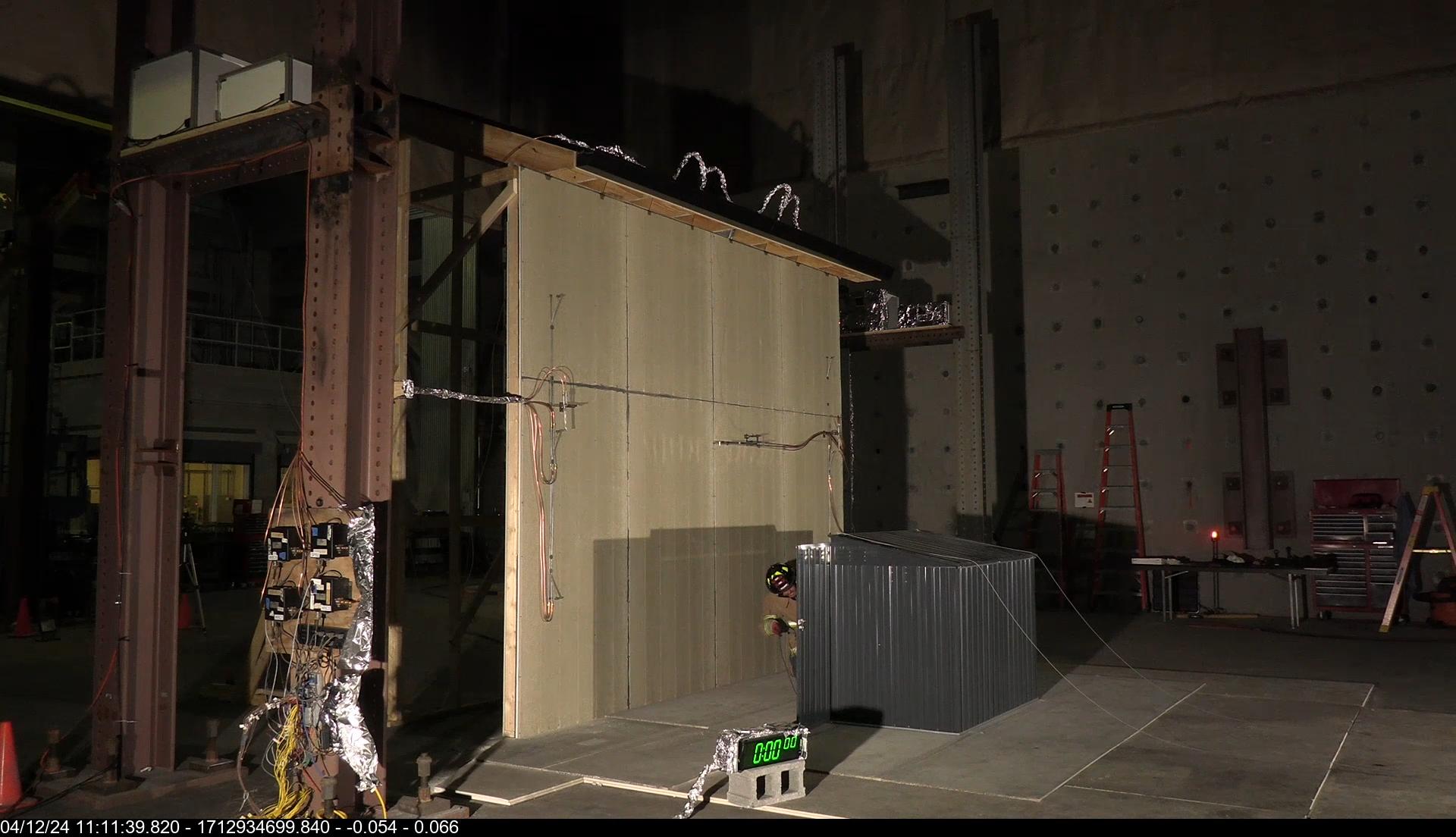

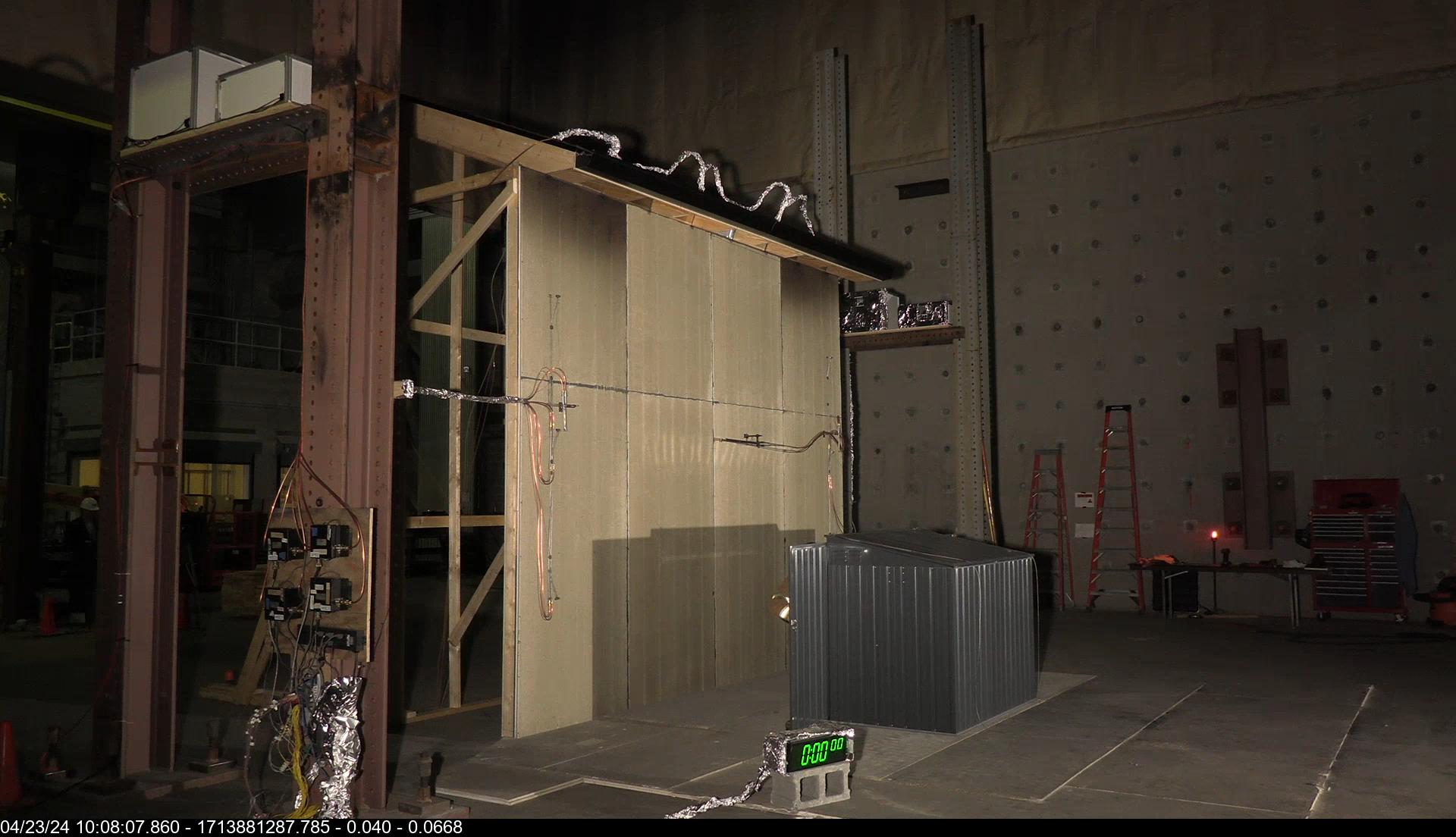

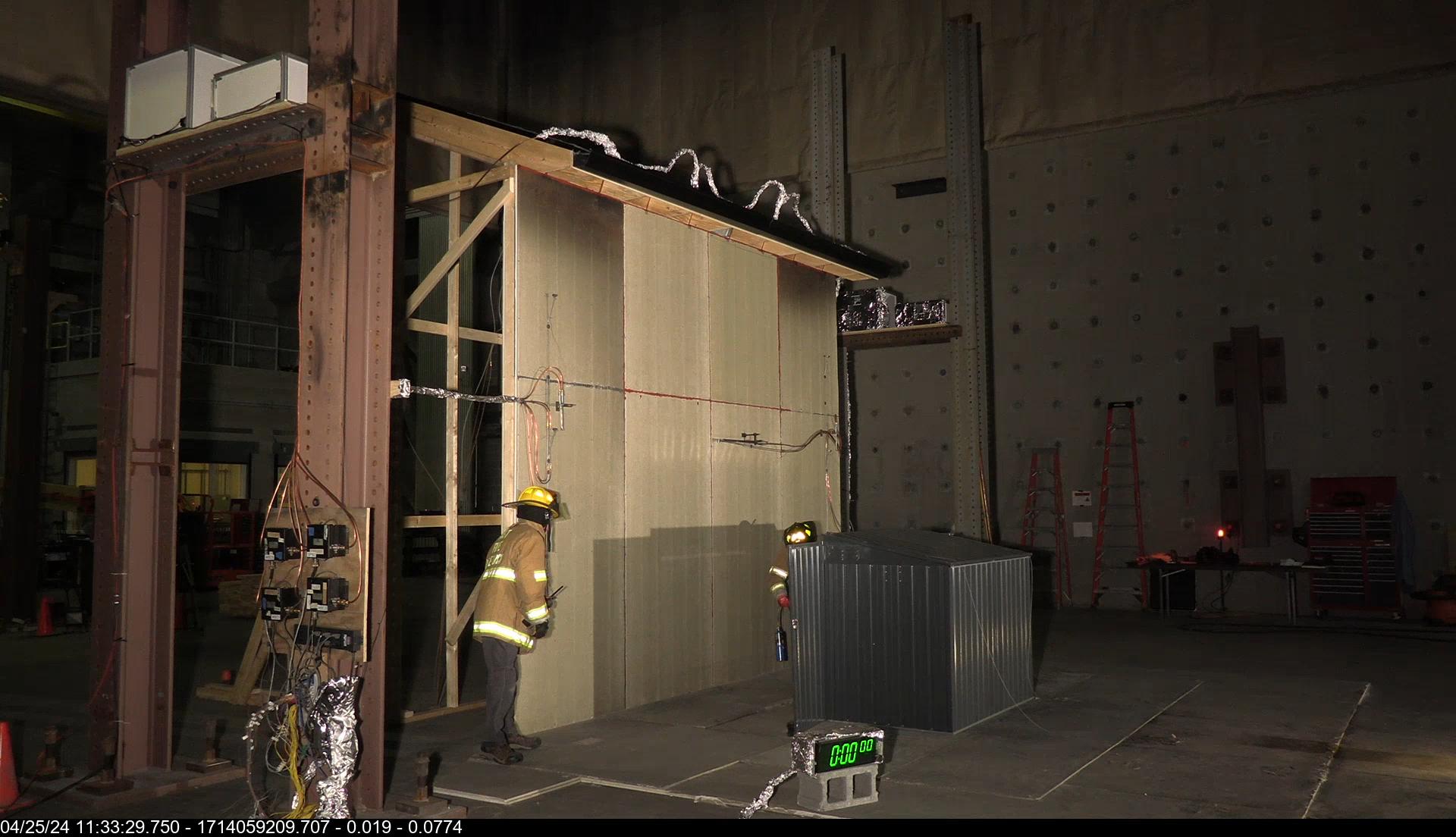

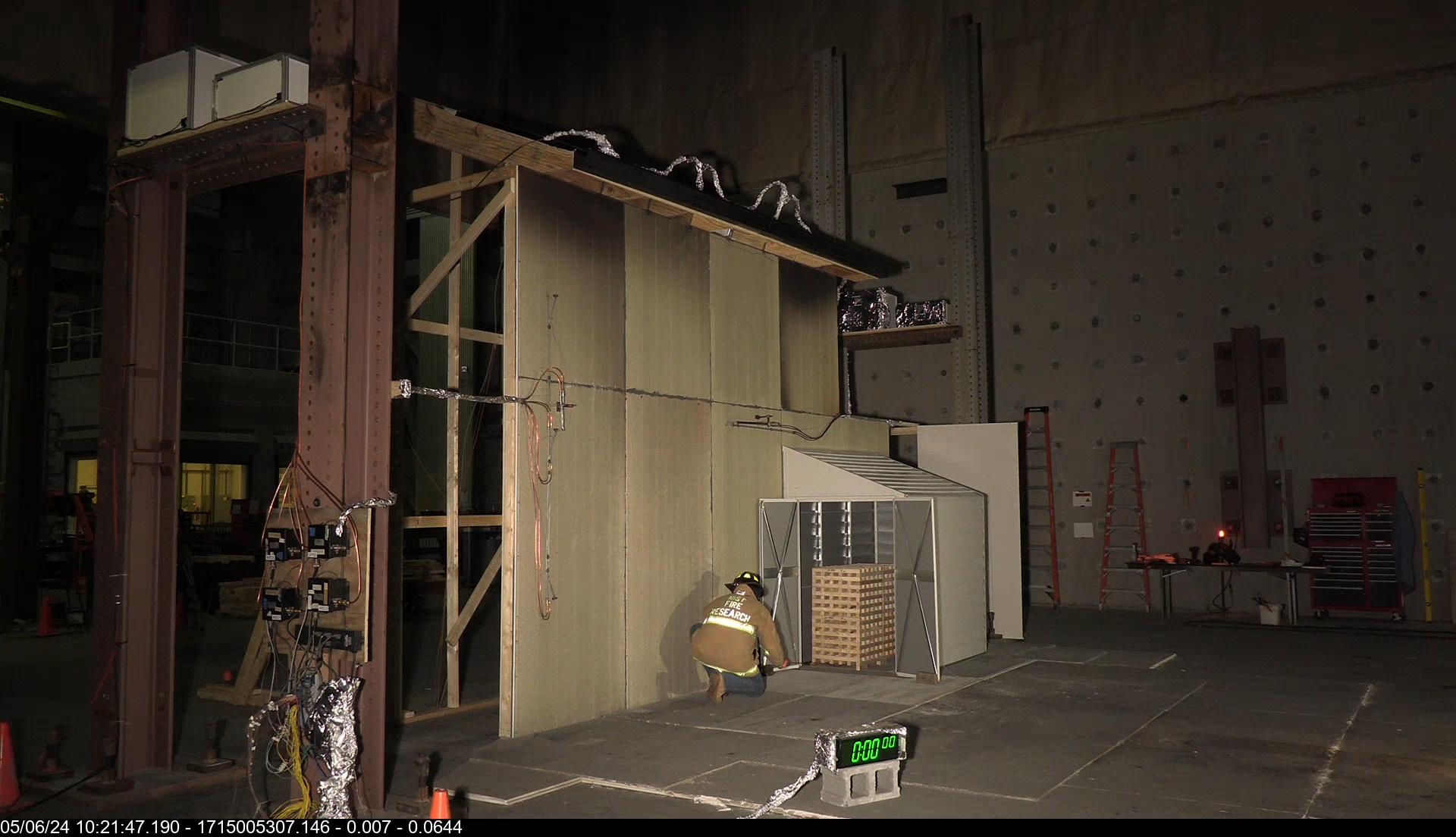

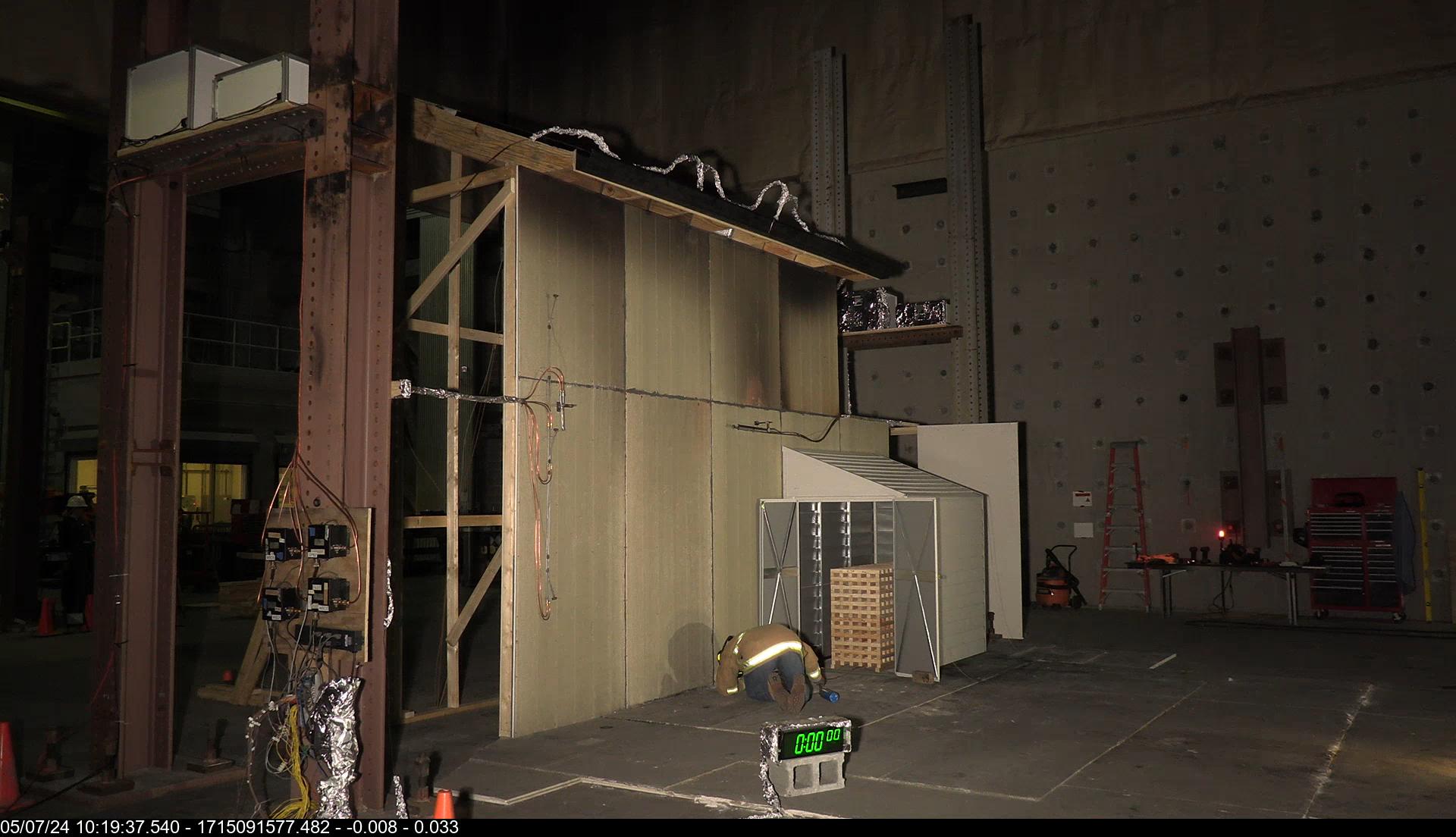

This experimental study involved noncombustible steel sheds at varying fuel loads and structure separation distances (SSDs) from the target structure. The target structure included an assembly of an exterior residential wall, a roof, and an eave vent. A range of measurements were taken during the experiments including heat release rate, heat flux, temperature, gas flow velocity, and gas species concentration using open-path absorption spectroscopy. Video and infrared cameras recorded the experiments. Thermal exposures from different types of sheds with different fuel loadings were found to be very repeatable when quantified in terms of heat release rate (HRR), heat fluxes and temperatures measured at the eaves. In the case of thermal exposures from the noncombustible steel sheds, ignition of the eaves was a function of flame jetting from the door opening and sustained incident peak heat flux at the eaves. Higher fuel packing density in the shed resulted in focused flame jetting and increased the likelihood of an eave ignition. The same fuel loading in different types of sheds resulted in different thermal exposures on the target structure. Thermal exposures to the target structure increased linearly with the fuel mass, however, the eave ignition was a function of flame jetting. Eave ignition started with glowing ignition in thermally vulnerable locations including sharp edges, corners, and joints of the rafters. The performance of three commercially available fire-resistant eave vents was assessed when subjected to much larger fire exposures (1.5 MW to 2.5 MW) compared to the fire exposure (300 kW) specified in the existing test methods. The vent performance was assessed primarily for flame penetration and temperature rise on the unexposed side of the vent. Amongst the commercially available vents tested in this experimental series, the performance of the intumescent coated baffle vents was superior compared to the intumescent coated honeycomb core vents during very high thermal exposures. Intumescent coated honeycomb core vents that comply with ASTM E2886 and are listed as WUI compliant products, failed to prevent flame penetration when exposed to large thermal exposures, particularly when eave ignition occurs. The current standardized eave vent test methods may not adequately expose the eave vents to real-WUI fire type of exposures. The knowledge generated from this experimental series will inform standards development organizations to consider revising the existing test methods for qualifying the vents for usage in WUI constructions. The exposure quantification data generated from this experimental series will be useful for hazard mitigation and reducing structure ignitions from large thermal exposures. The exposure quantification information will be useful in managing thermal exposures from auxiliary fuels and other exposures, particularly in WUI communities.

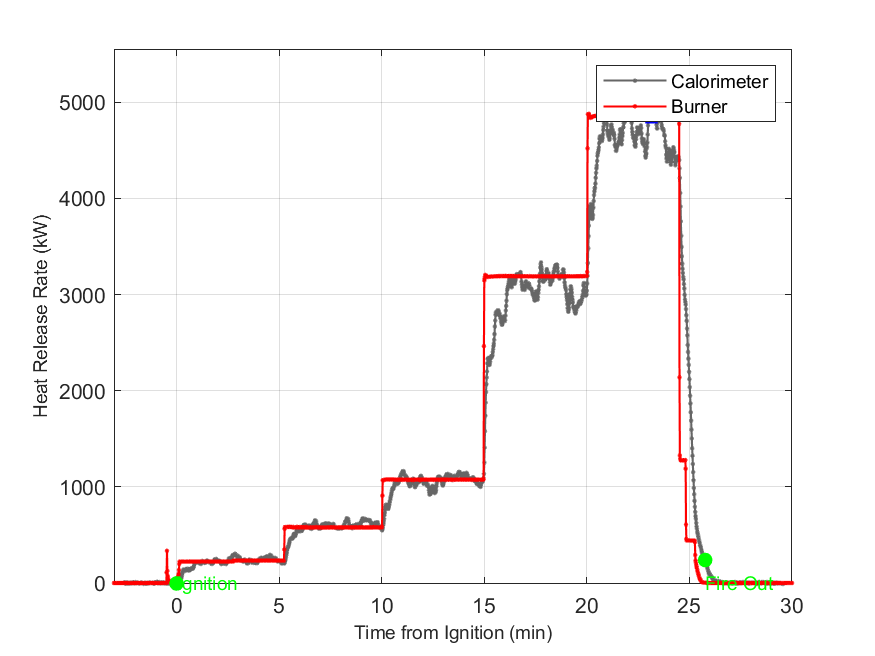

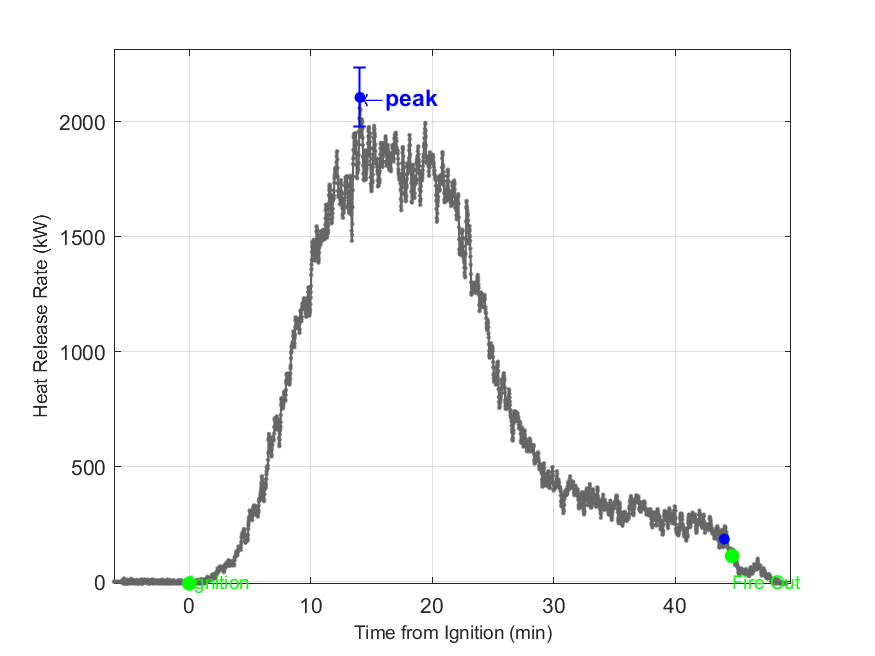

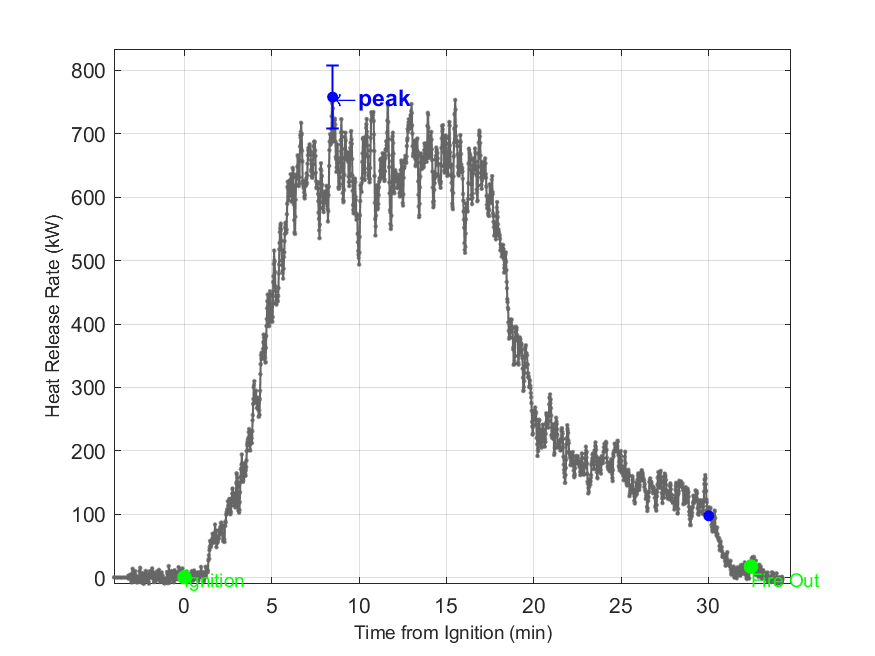

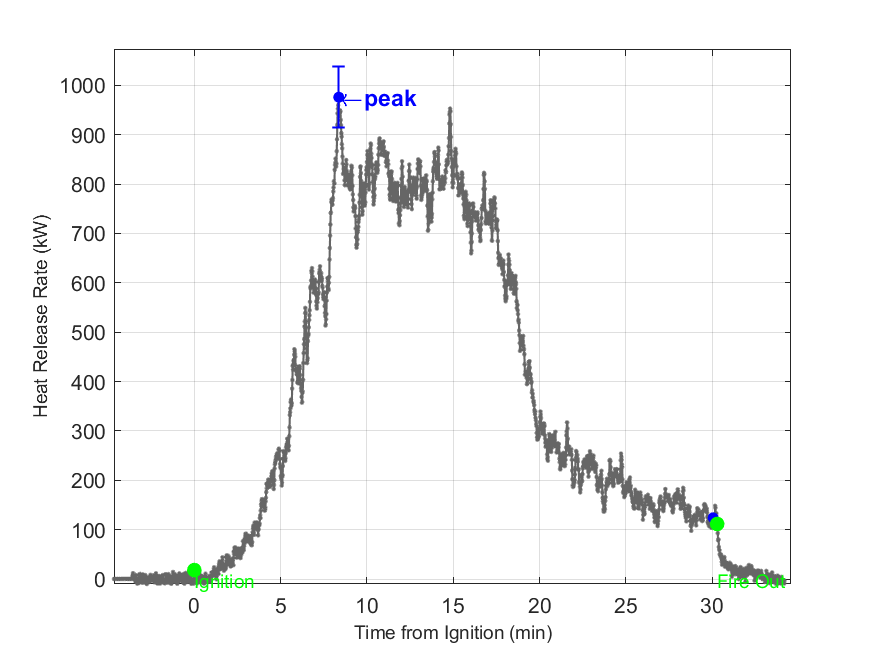

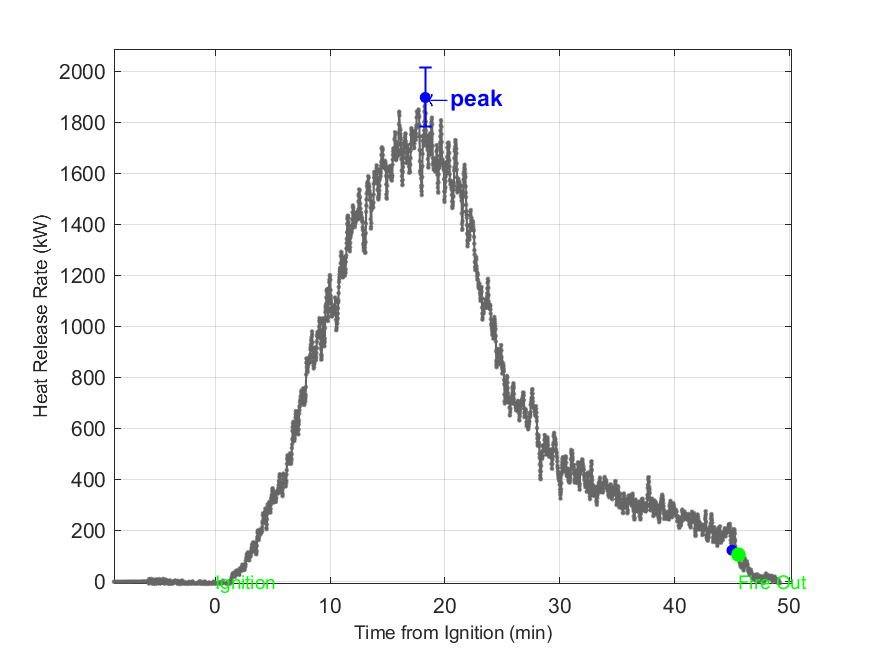

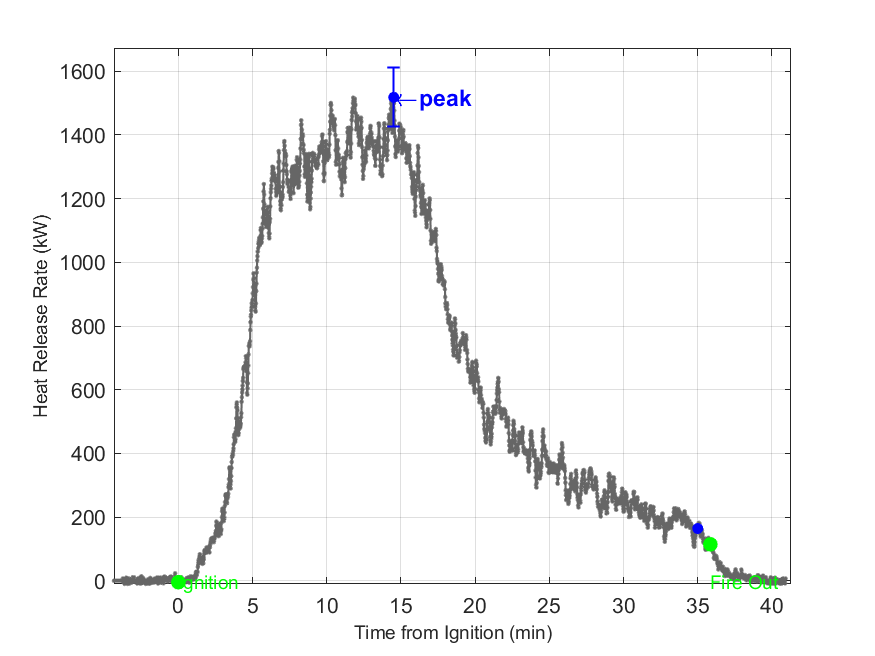

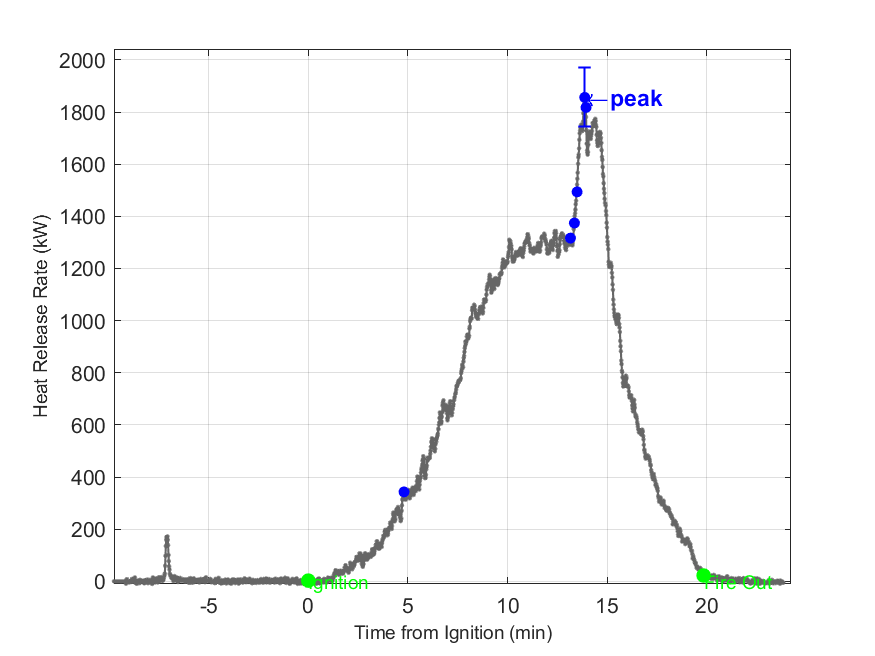

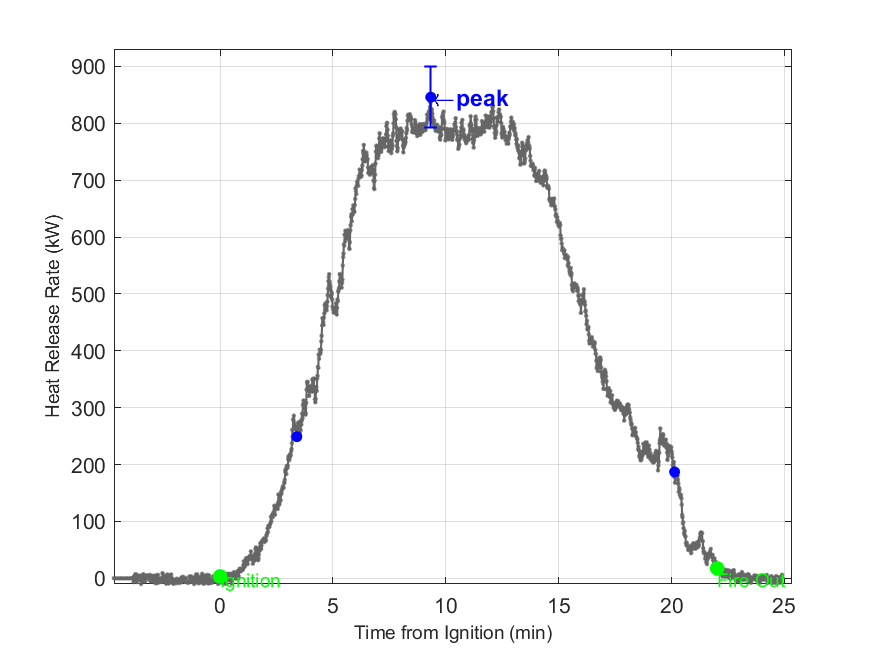

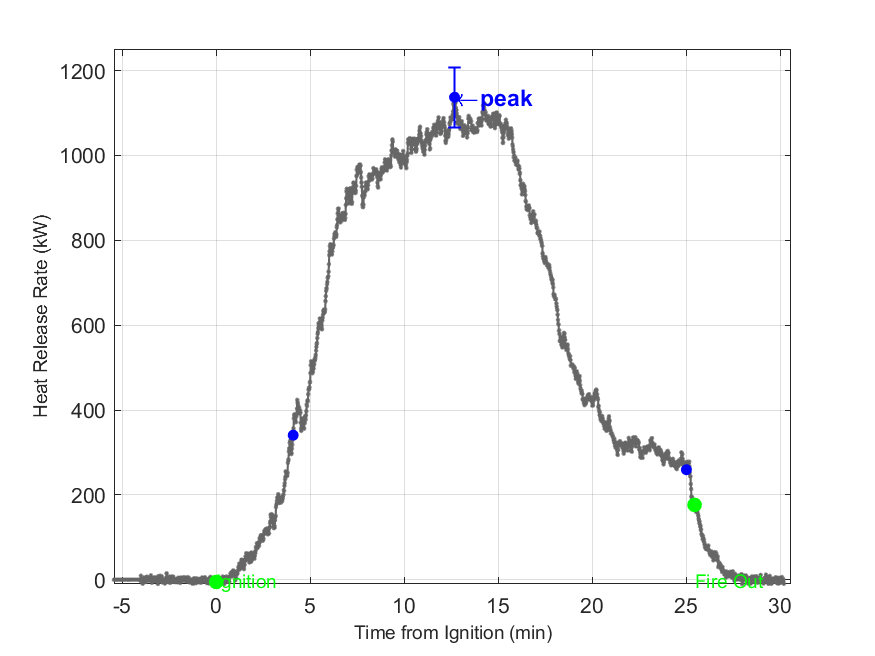

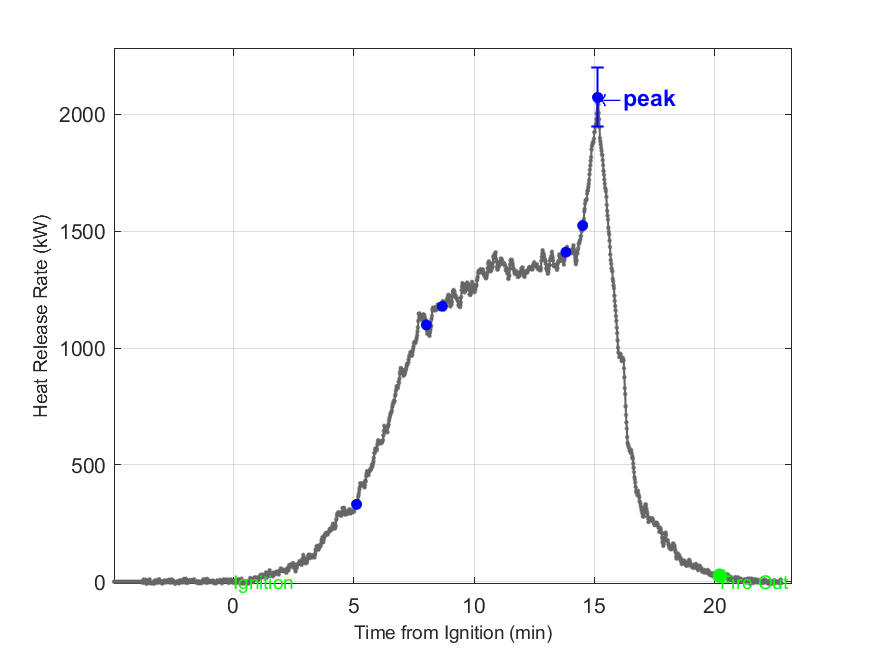

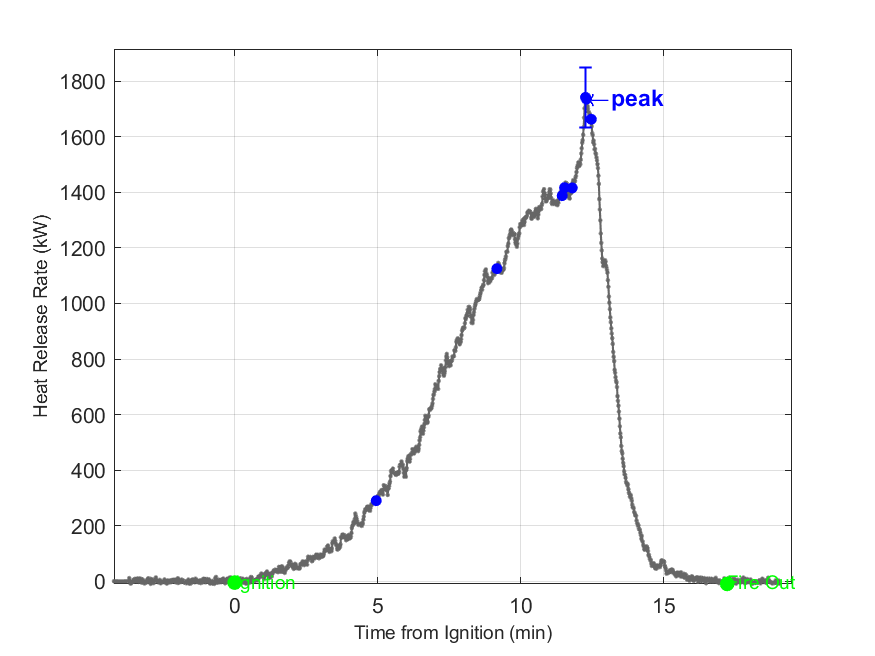

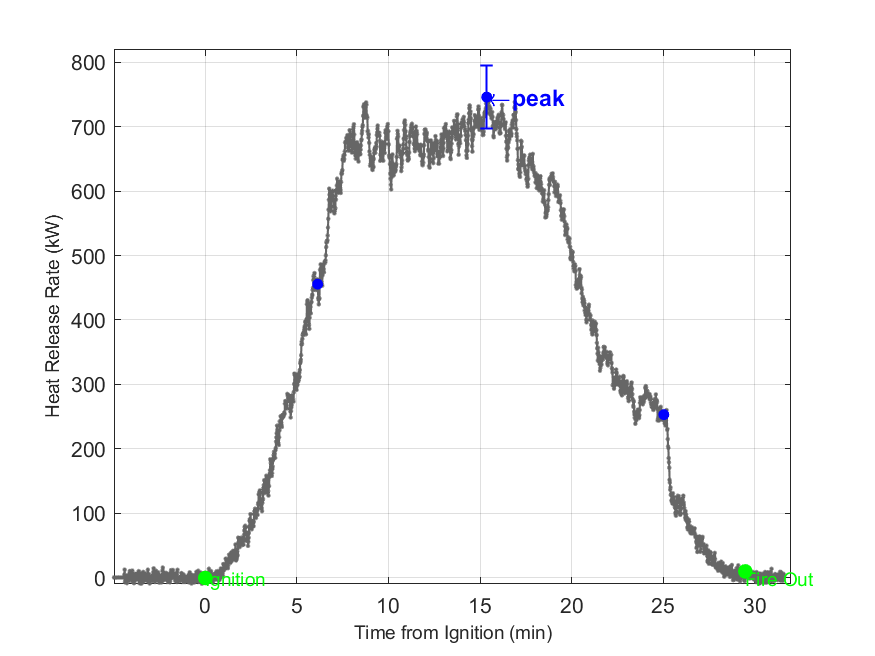

| Experiment Name | Plot of Heat Release Rate | Ignition Photo | Date/Time Sort descending | Specimen | Fuel Type | Test Duration (min) | Total Heat Released (MJ) | Peak HRR (kW) |

|---|---|---|---|---|---|---|---|---|

| NGQC_15m_50kgs_R2 |

|

|

Tube Burner | Natural Gas | 25.77

|

2,800

|

5,049

|

|

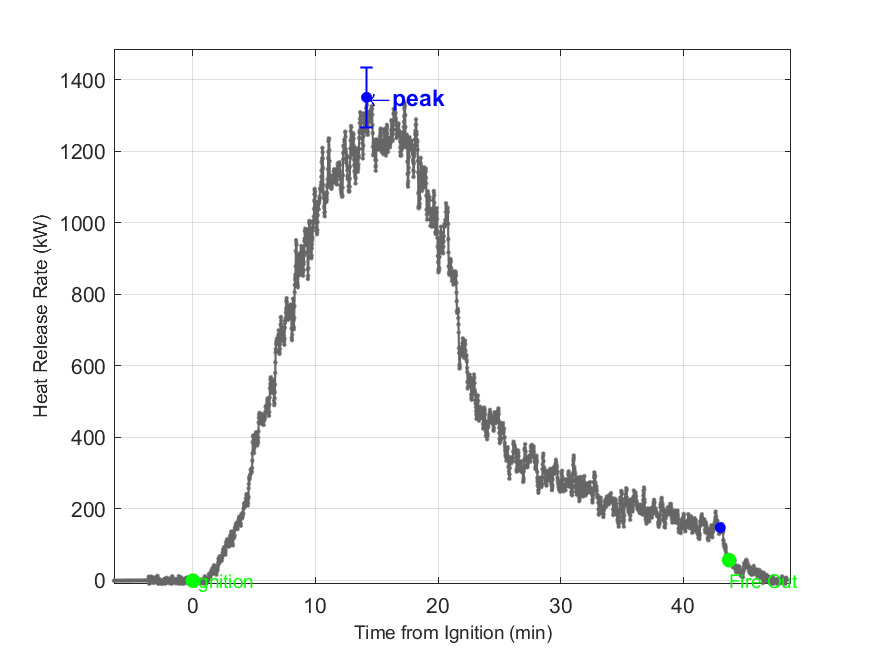

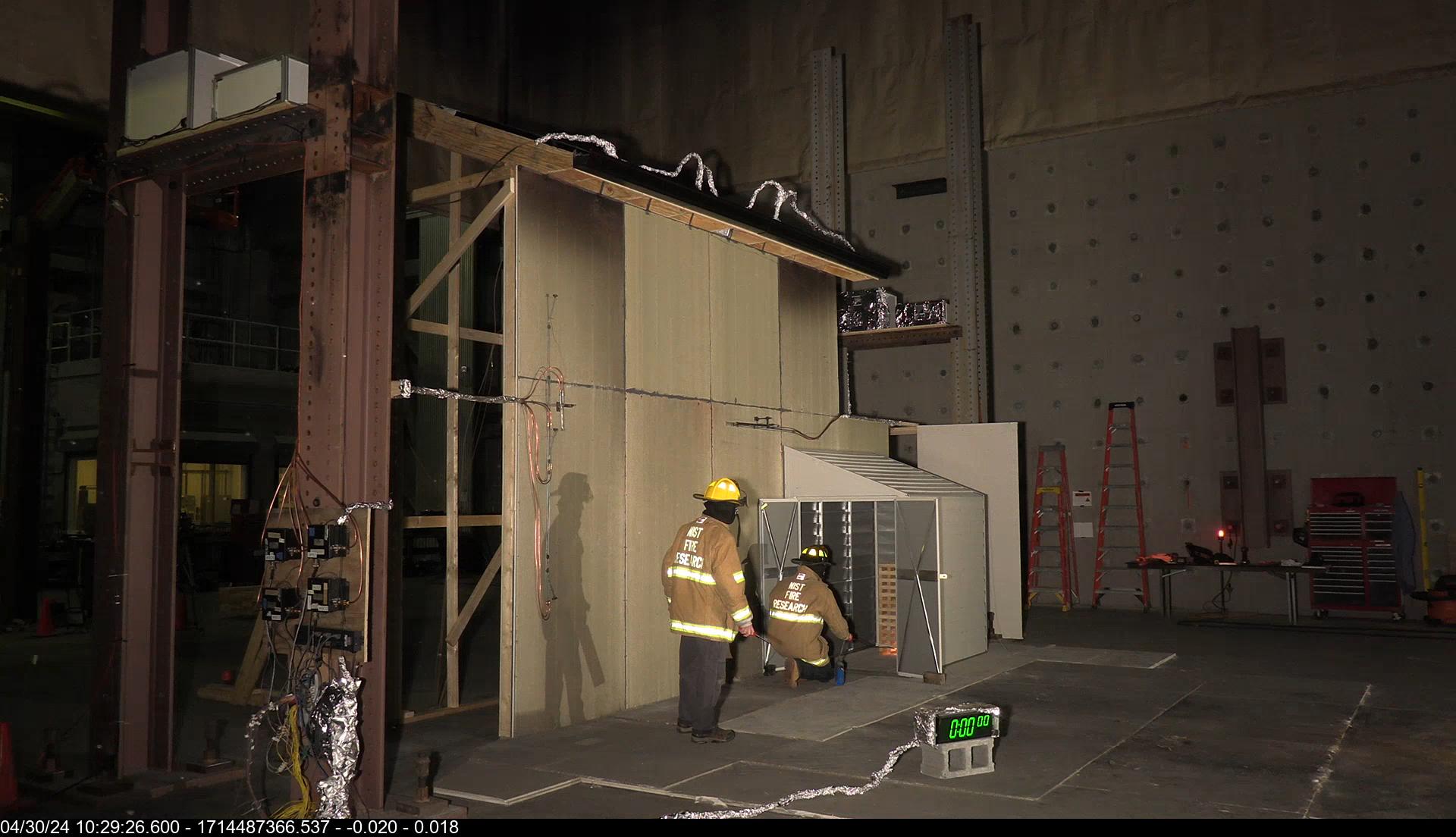

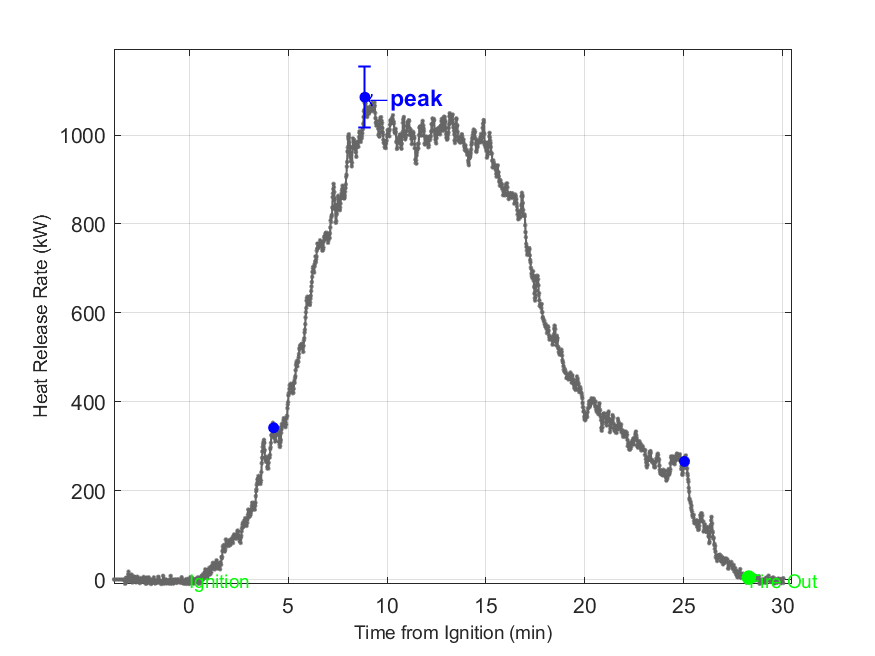

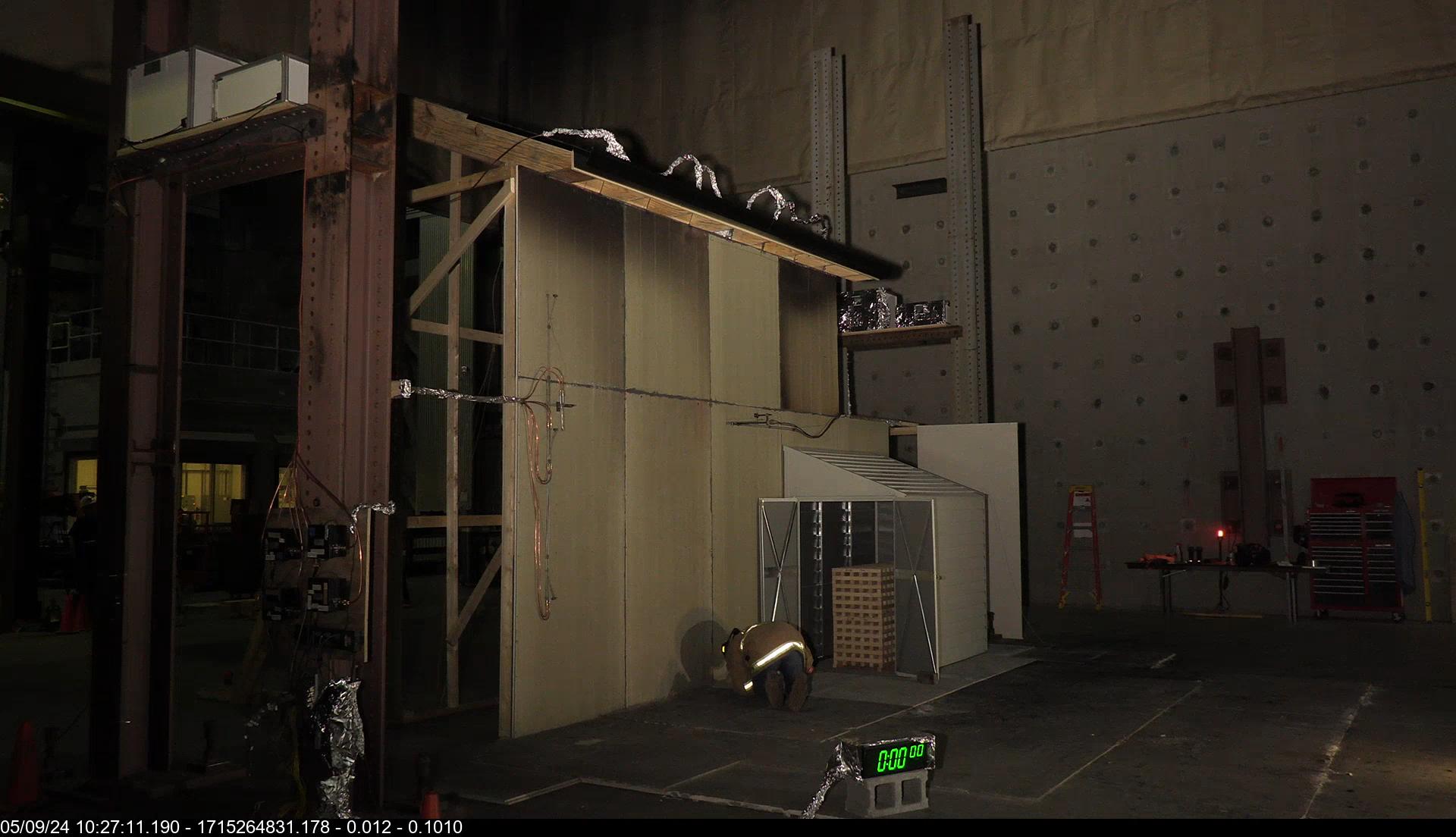

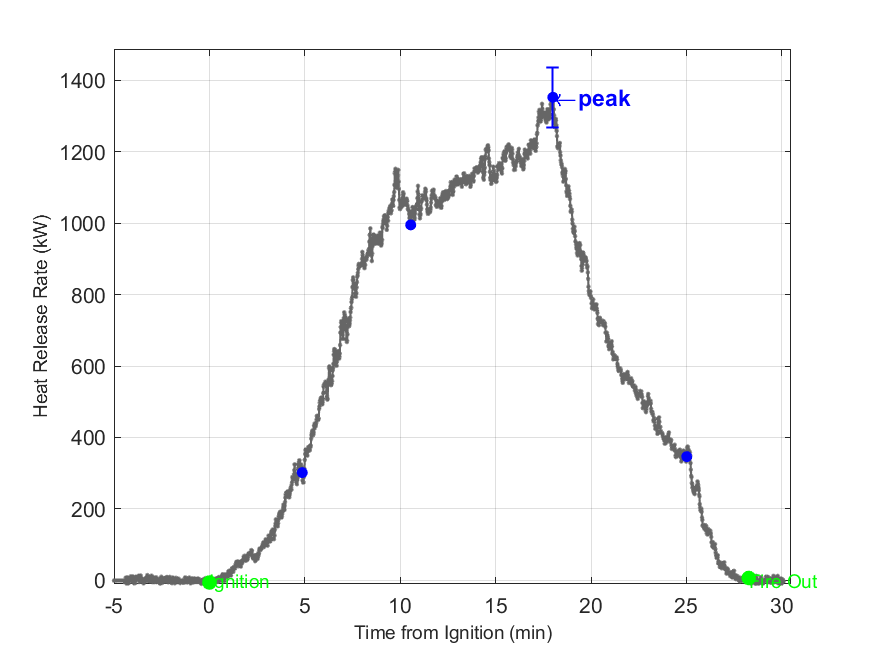

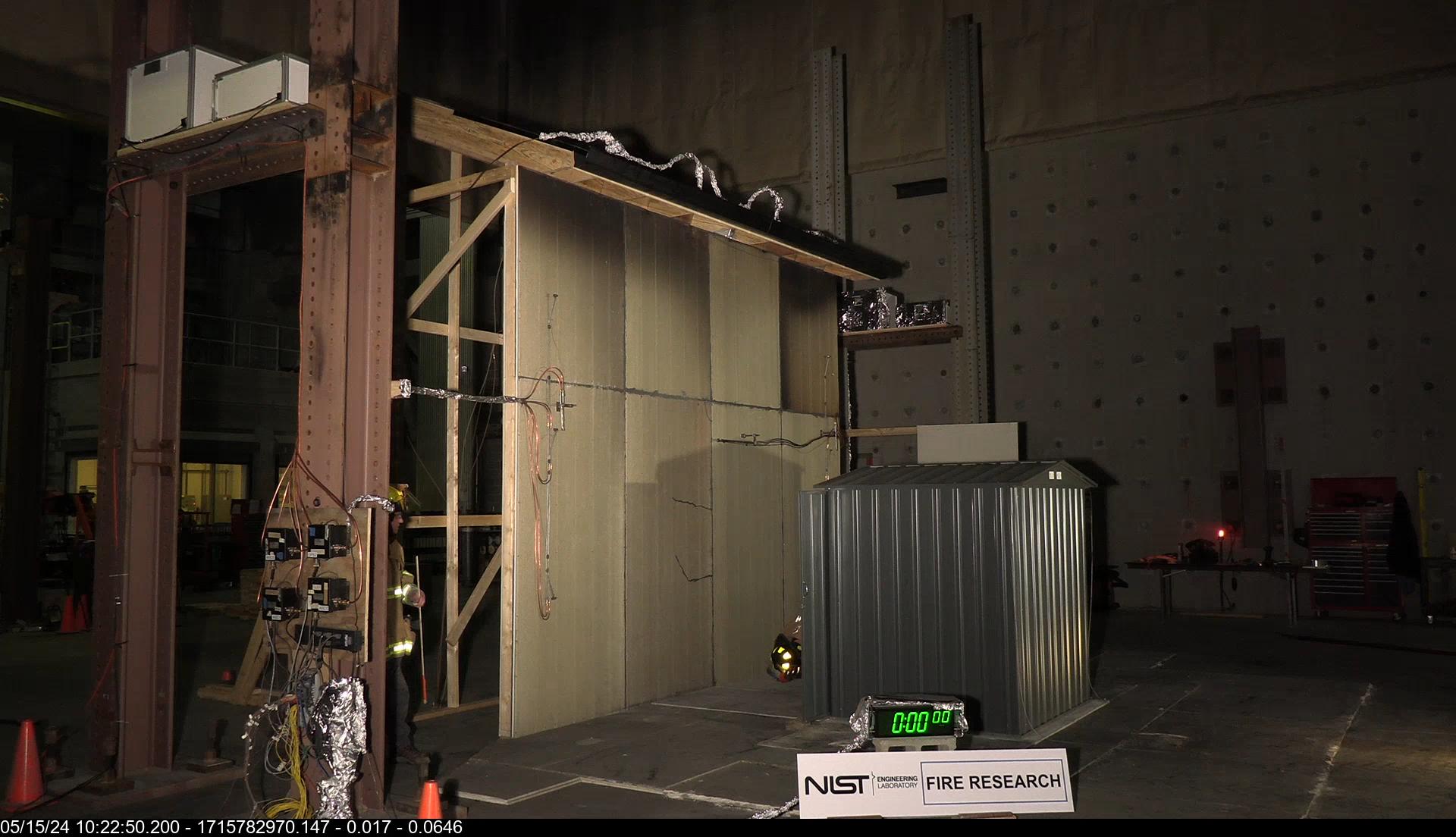

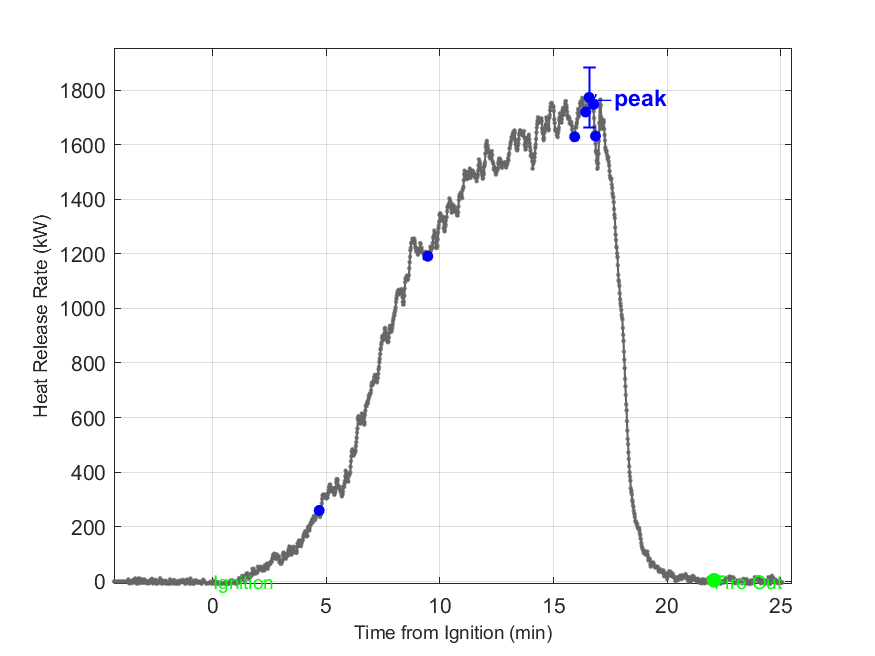

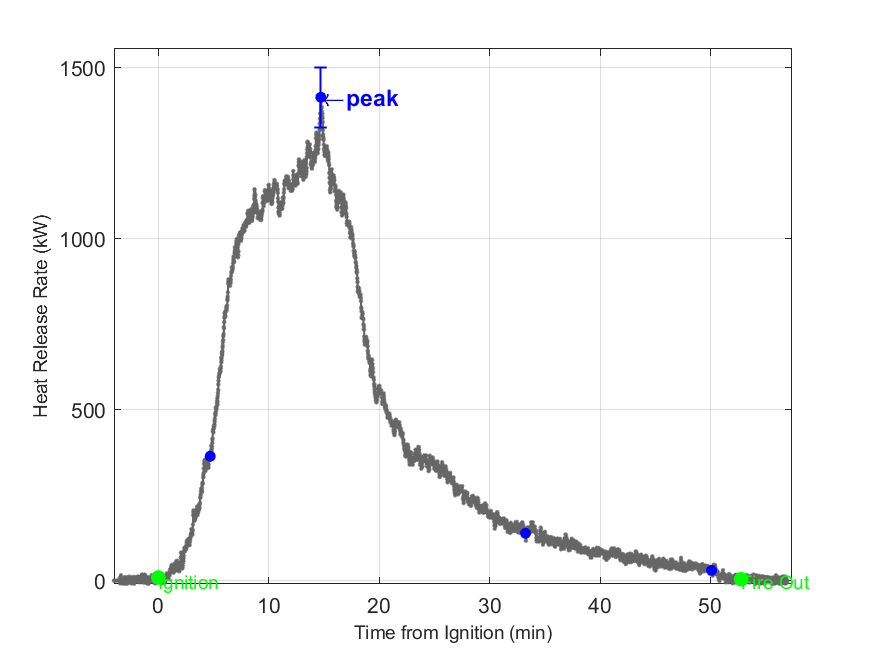

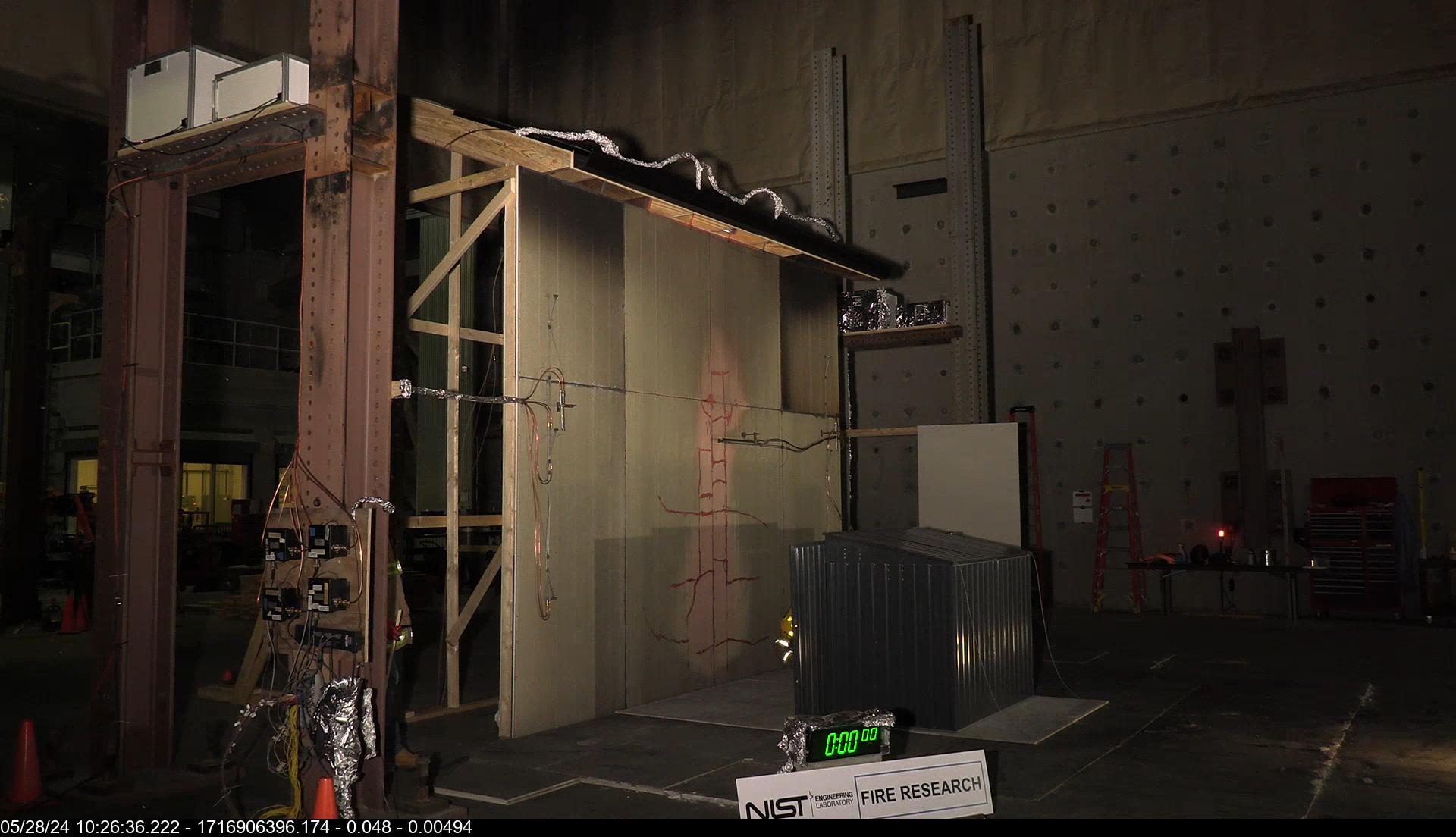

| p1_SNm0 |

|

|

wood cribs in steel shed | Cellulose | 43.73

|

1,399

|

1,351

|

|

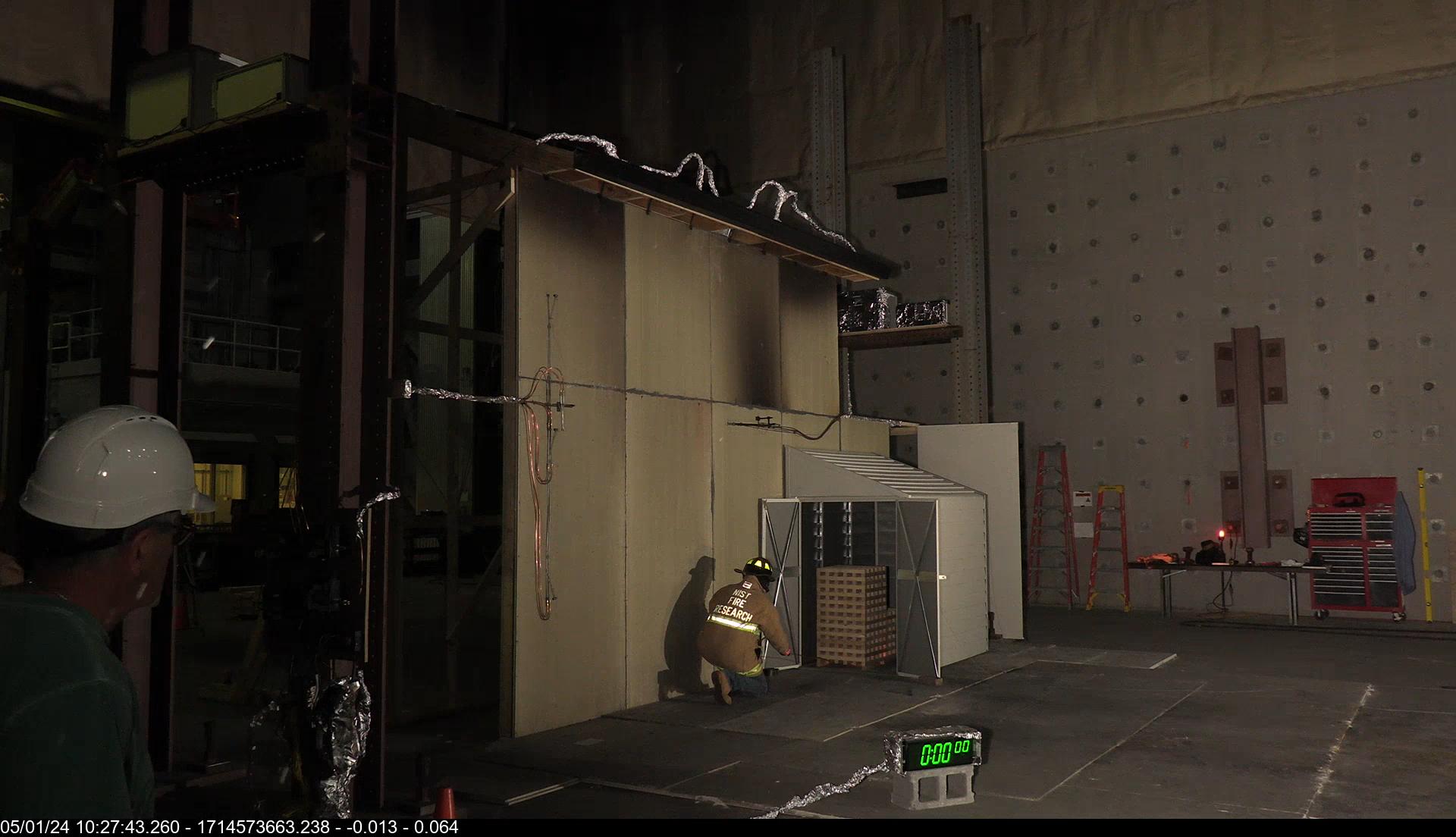

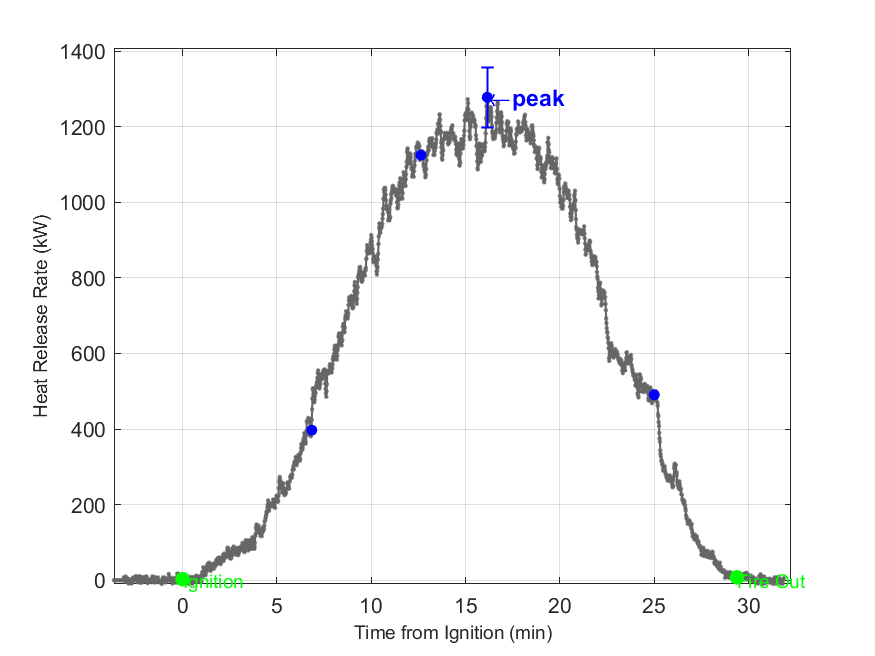

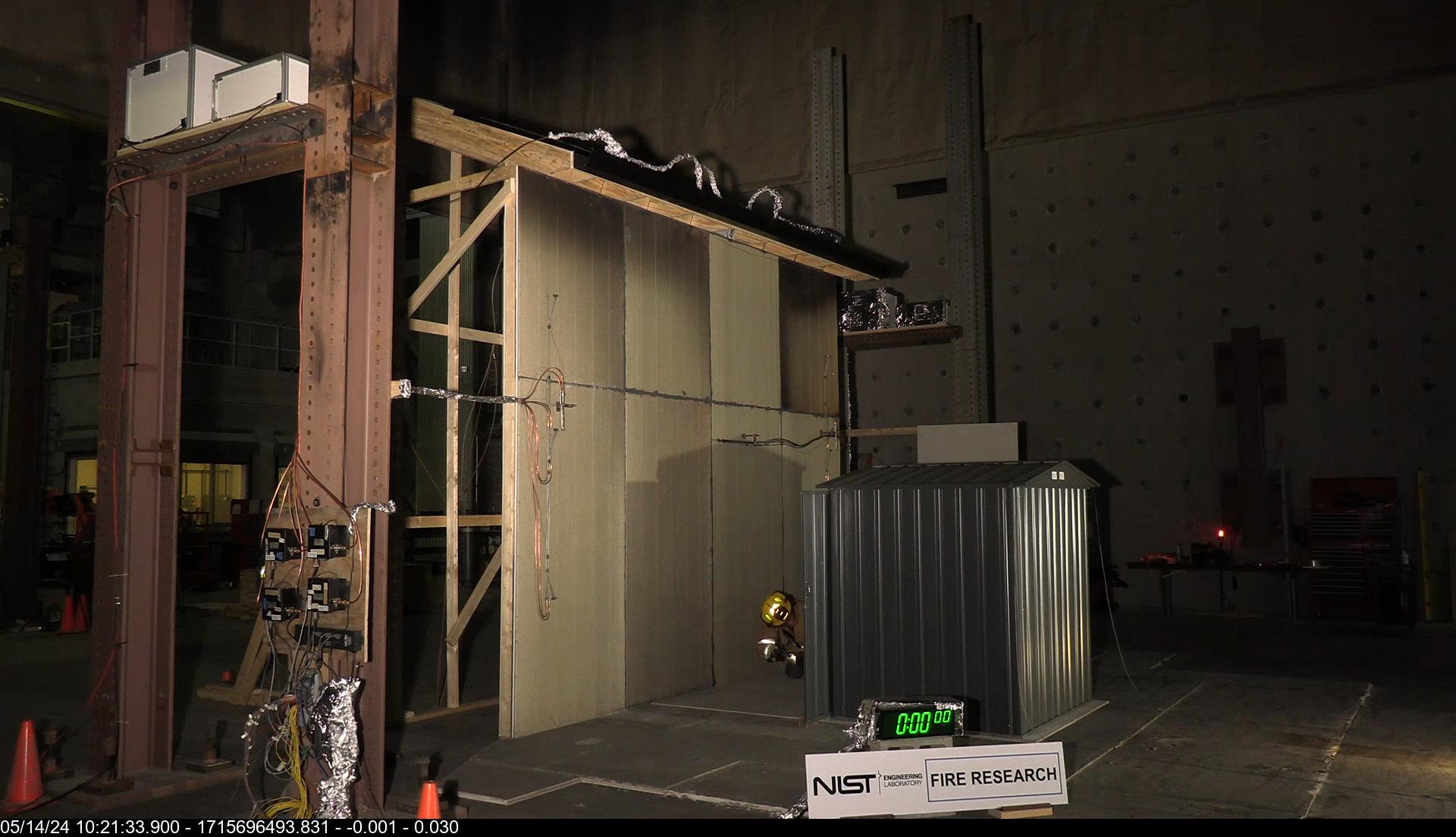

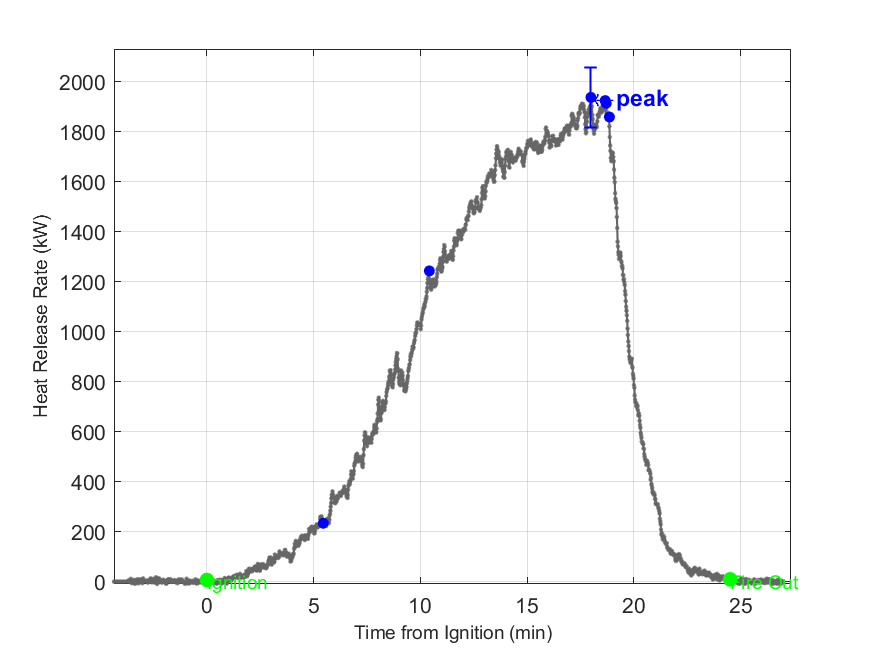

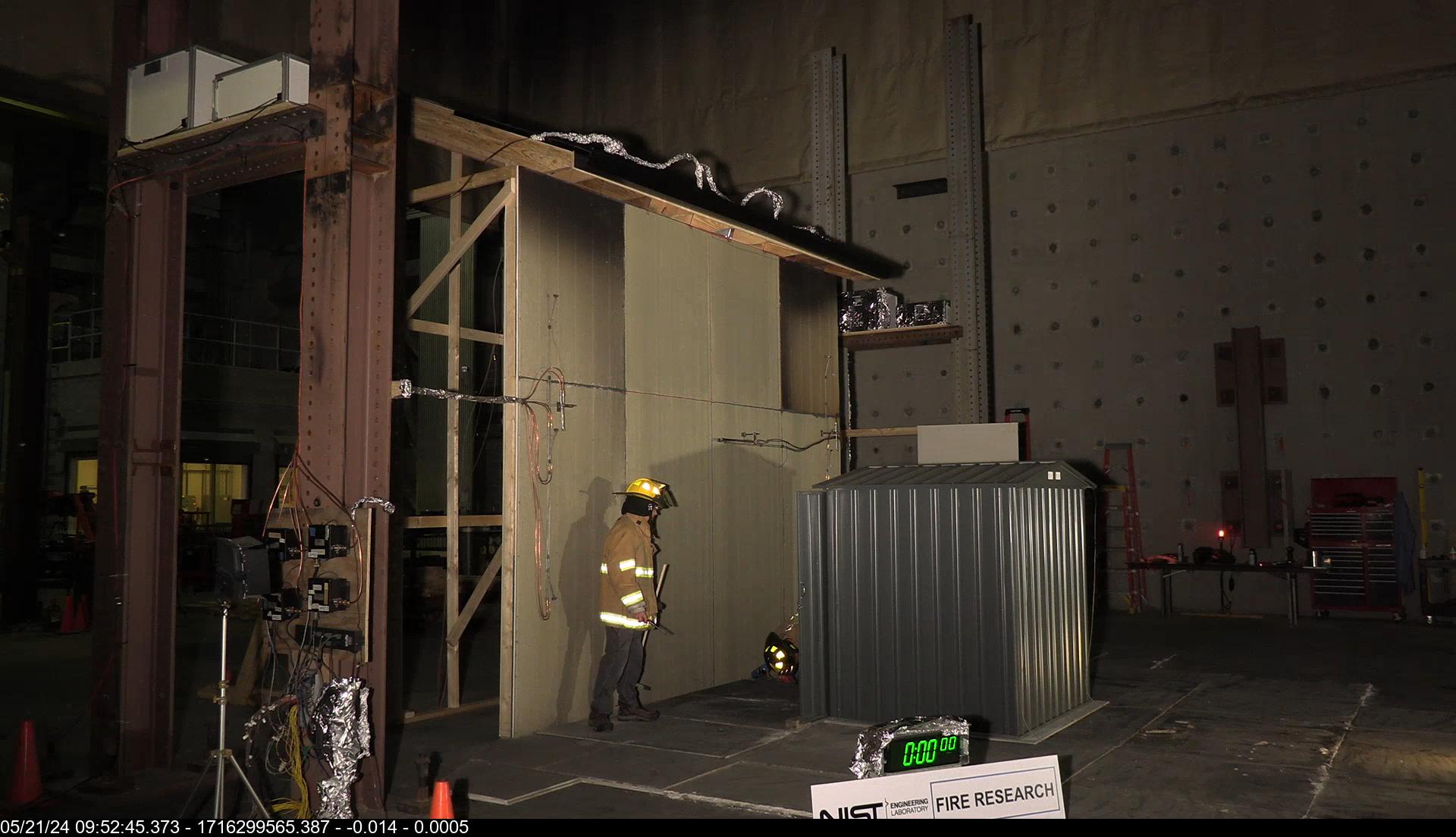

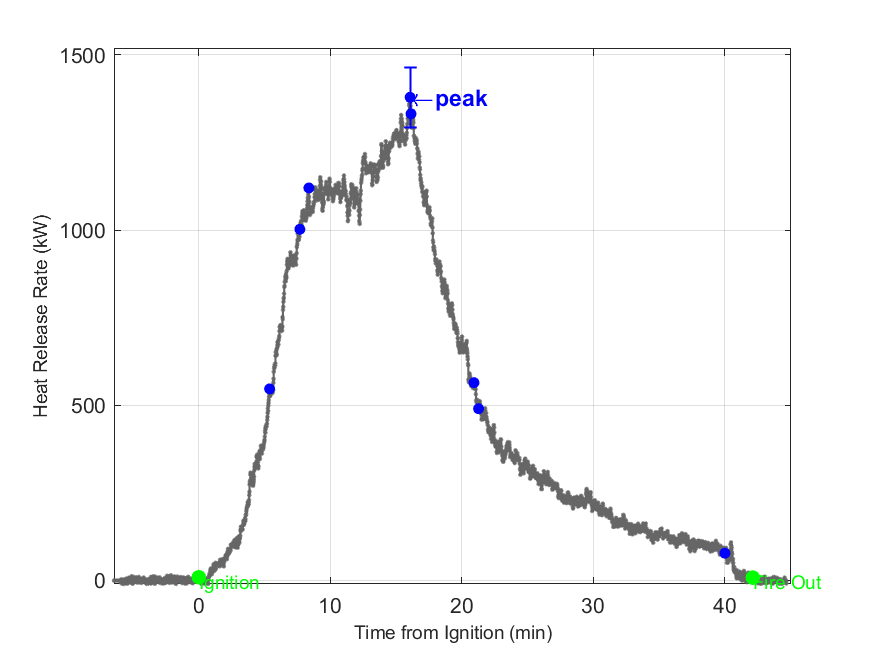

| p2_SVSh0 |

|

|

wood cribs in steel shed | Cellulose | 44.68

|

2,196

|

2,105

|

|

| p3_SNl0 |

|

|

wood cribs in steel shed | Cellulose | 32.43

|

685

|

758

|

|

| p4_SCl0 |

|

|

wood cribs in steel shed | Cellulose | 30.28

|

757

|

976

|

|

| p5_SNh0 |

|

|

wood cribs in steel shed | Cellulose | 45.57

|

2,015

|

1,897

|

|

| p6_SVSl0 |

|

|

wood cribs in steel shed | Cellulose | 35.85

|

1,453

|

1,518

|

|

| e7_SCh0-5 |

|

|

wood cribs in steel shed | Cellulose | 19.83

|

825

|

1,856

|

|

| e8_SCl0-5 |

|

|

wood cribs in steel shed | Cellulose | 22.02

|

613

|

846

|

|

| e9_SCm0-5 |

|

|

wood cribs in steel shed | Cellulose | 25.45

|

947

|

1,137

|

|

| e10_SCh0-5-R1 |

|

|

wood cribs in steel shed | Cellulose | 20.22

|

882

|

2,073

|

|

| e11_SCh0-5-R2 |

|

|

wood cribs in steel shed | Cellulose | 17.22

|

560

|

1,742

|

|

| e12_SNl0-0 |

|

|

wood cribs in steel shed | Cellulose | 29.48

|

719

|

746

|

|

| e13_SNi0-0 |

|

|

wood cribs in steel shed | Cellulose | 28.28

|

902

|

1,085

|

|

| e14_SNm0-0 |

|

|

wood cribs in steel shed | Cellulose | 29.38

|

1,115

|

1,278

|

|

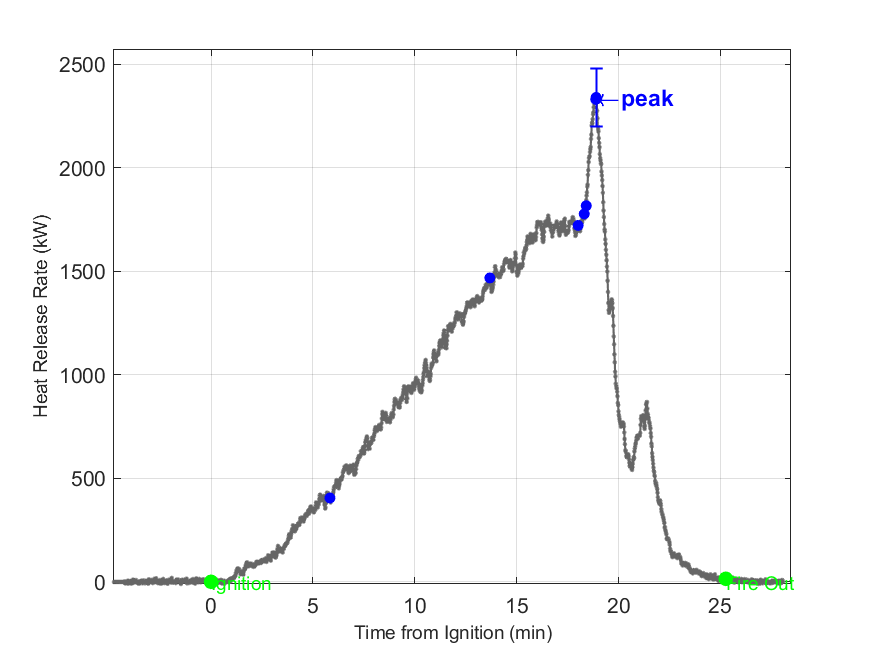

| e15_SNh0-0 |

|

|

wood cribs in steel shed | Cellulose | 25.27

|

1,226

|

2,340

|

|

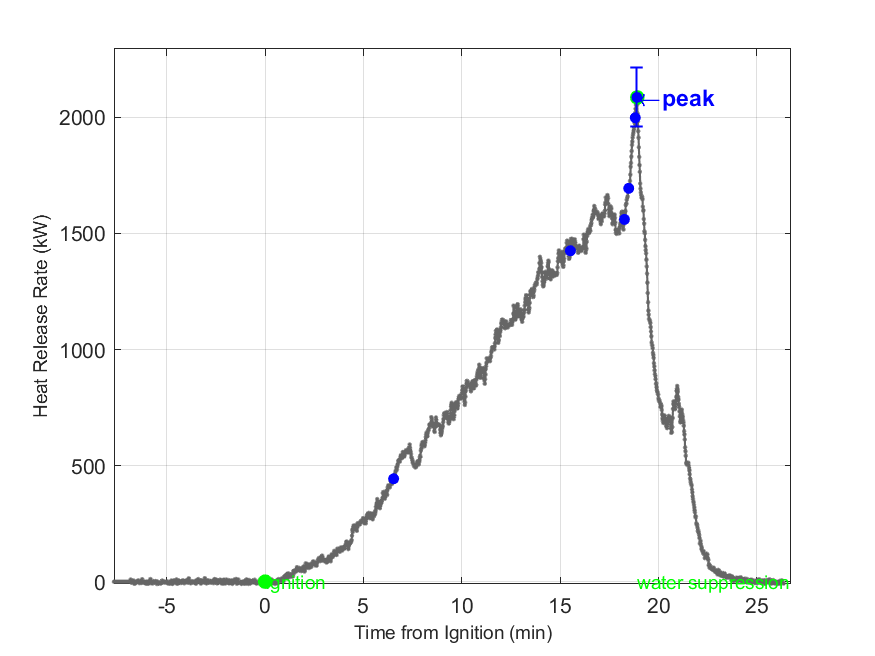

| e16_SNh0-0-R1 |

|

|

wood cribs in steel shed | Cellulose | 33.07

|

1,054

|

2,086

|

|

| e17_SVSl0-5 |

|

|

wood cribs in steel shed | Cellulose | 28.27

|

1,115

|

1,352

|

|

| e18_SVSh0-5 |

|

|

wood cribs in steel shed | Cellulose | 24.50

|

1,188

|

1,937

|

|

| e19_SVSh0-5-R1 |

|

|

wood cribs in steel shed | Cellulose | 22.07

|

1,050

|

1,773

|

|

| e20_SCh0-5 |

|

|

wood cribs in steel shed | Cellulose | 42.12

|

1,260

|

1,379

|

|

| e21_SCh0-5-R1 |

|

|

wood cribs in steel shed | Cellulose | 52.78

|

1,275

|

1,413

|

|

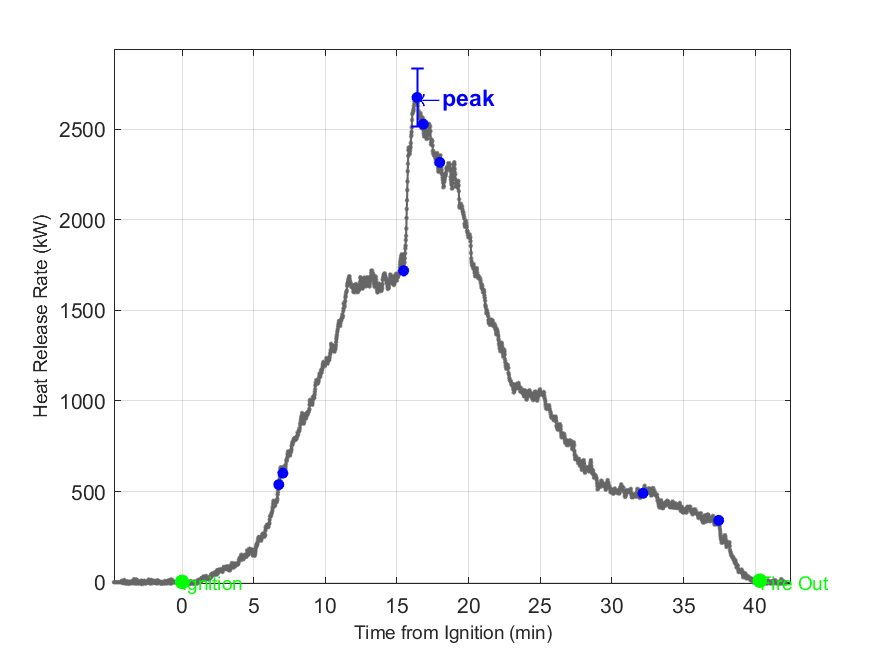

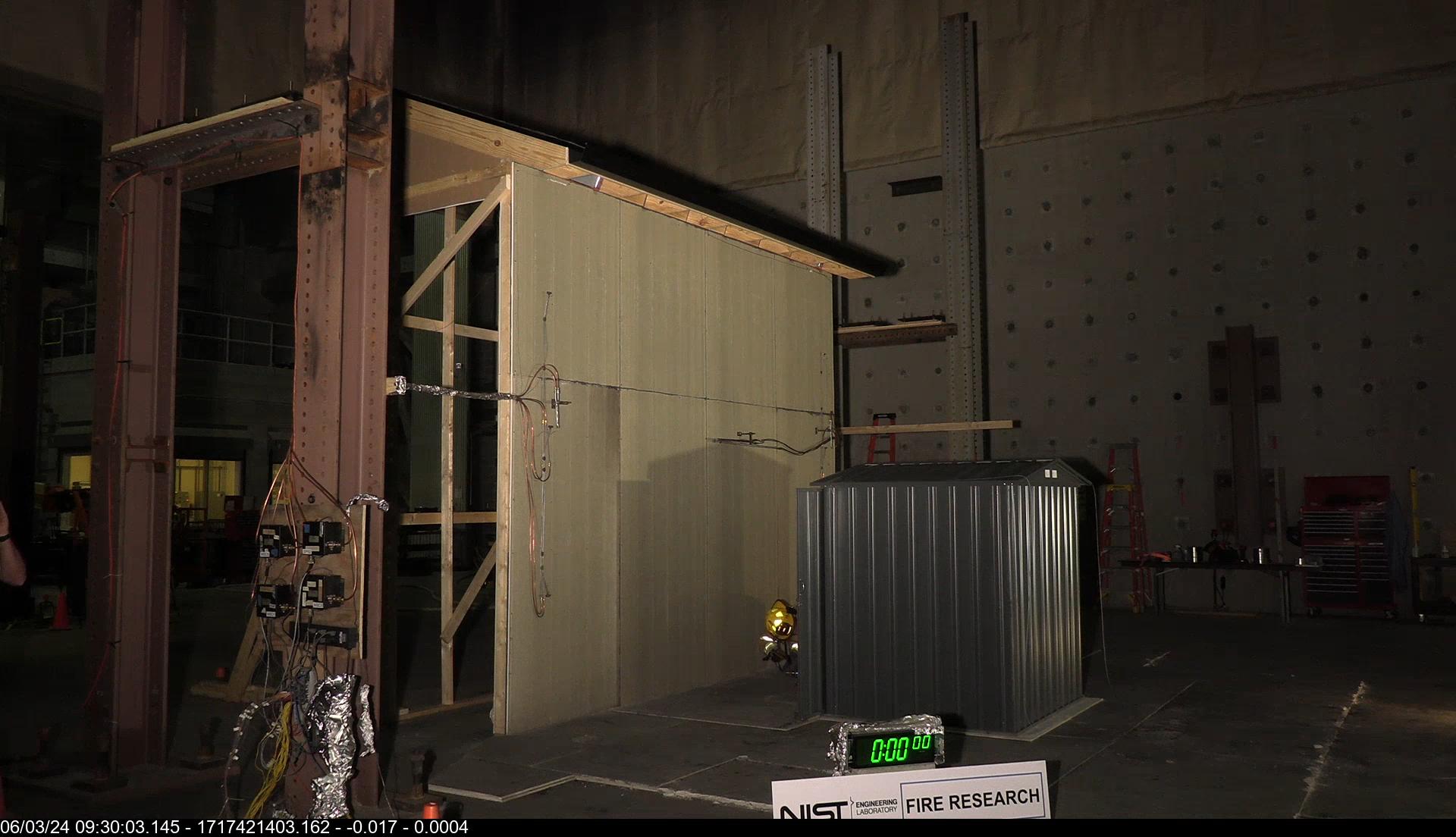

| e22_SVSh0-5 |

|

|

wood cribs in steel shed | Cellulose | 40.32

|

2,193

|

2,674

|

Bryant, R. and Bundy, M. The NIST 20 MW Calorimetry Measurement System for Large-Fire Research, Technical Note (NIST TN) 2077, 2019

https://doi.org/10.6028/NIST.TN.2077

NIST Fire Calorimetry Database (FCD)

https://doi.org/10.18434/mds2-2314